I have enrolled in the Maiwa School of Textiles Natural Dye Course. This is an online course over 10 weeks teaching the basics of natural dyeing. This is offered by Maiwa (pronounced May-wa) located in Vancouver on Granville Island, Canada. I ordered the accompanying dye kit from Maiwa as that seemed smart. Everything I need is in there from mordants, samples fabrics and yarns, tag systems, dyes, etc. As I run out I can replenish closer to home. Since I already dye a a lot using chemical dyes, I had a fairly good dye studio set up. But I did need to purchase some stainless steel pots as the ones I normally use are mostly aluminium.

The course began 6 May for me in NZ and the first two weeks were all about setting up your dye studio and getting your fibres ready for dyeing. I had to scour (a fancy word for wash) almost all of the fabrics and yarn, then mordant them. Two systems were used: one for protein fibres (wool, silk) and one for cellulose (cotton, hemp, linen). This was time intensive but under normal circumstances this is super easy as you would only be doing one project at a time! Often the pots had to sit overnight and be rinsed in the morning. I tried to reuse as much of the pot water that I could – though still having to “top up”.

This week was the first foray into actual dyeing. Module 3 begins dyeing protein fibres, starting with yarn then fabric. This is the most exciting for me as I dye heaps of wool for my own weaving and to sell. Here I used 6 natural bases: madder, marigold, cochineal, Himalayan rhubarb, brazilwood and lac.

The colours created were absolutely amazing. The Himalayan rhubarb produced the most lovely caramel, and the deep purple of the lac was incredible. All the colours work really well with and off each other. I can already imagine lots of woven pieces!

My water is quite hard so I did not leave my dyes to set overnight. I let the pots cool down completely and then rinsed out the fibres. These now have to “set” for about 2 weeks until they can be really washed. That is a difference to chemical dyes as they are ready for use immediately.

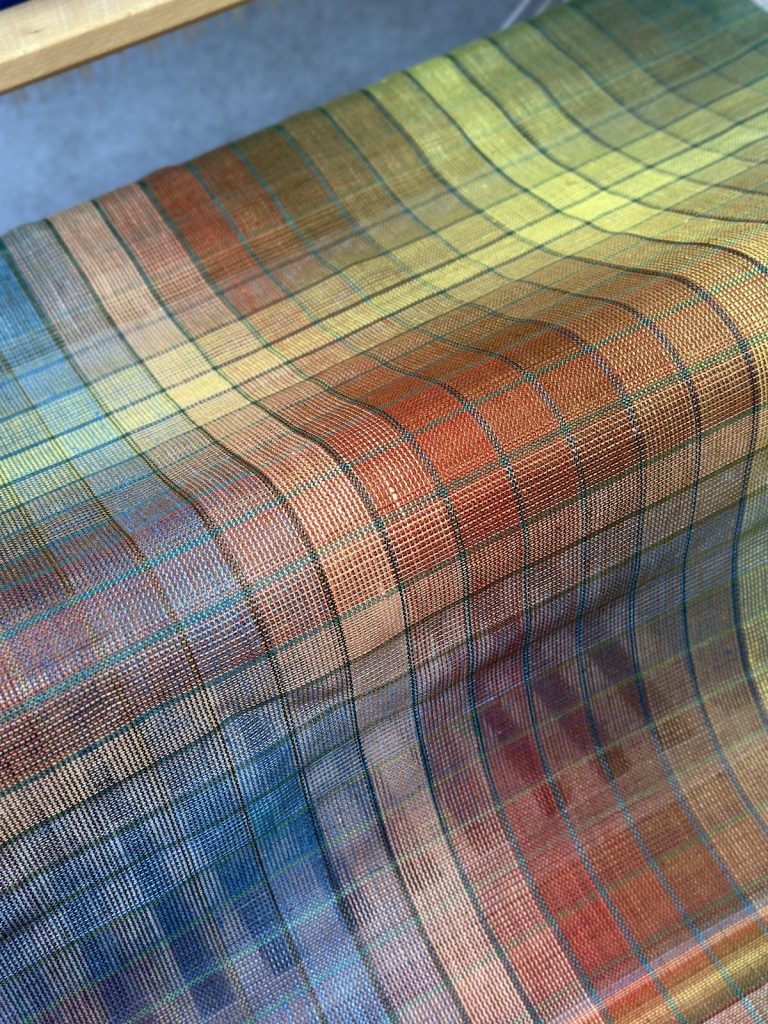

Otherwise this week I did some weaving and got the shawls off the loom last night. This was a time consuming set up and weave using 14 naturally dyed ultra fine linen colours in a full gradient across the wrap, using silk as separators. I’ve had the idea for a while but not the time. That is why I love the non-market winter season. I can devote myself to design work and creating more involved pieces. Now they need to be washed, trimmed and finished. One will go in my shop, the other is private.

And I am still knitting away on Sweater No 11 from My Favourite Things. I am working with 4ply possum Merino and silk mohair held together. I hand dyed the wools in gradient shades of green. This is incredibly soft, pretty much like the capes I sell but in a jumper format! A simple but long knit. I got to the point of joining the shoulders and knitting the bodice quite quickly. But the body of the jumper took forever. Knitting in the round row after row. Now I am at the body hem ribbing and that is done in twisted rib. I wasn’t going to do that, but then I put my Big Girl Pants on and decided to do it. I knew I would be unhappy for not working the rib that way. Twisted rib means you are knitting each stitch through the back loop – both knit and purl., all 280 stitches. I am halfway done with that (going for 11cm). And when the body is finished (and since it is so much fun), next up is the turtleneck – in twisted rib!